For the past several months I’ve been posting about AR mag holders. Well, they’re finally live on the website. Check ’em out here. And for a limited time, you can get one free! Just spend $50 on the website and write in the order comments, or message us that you would like one. That’s it.

They’re designed and printed by us, all in house. Now you may be saying to yourself “phft, it’s just 3d printed crap.” And a year ago, I would have agreed with you. But now, seeing how far technology has come in the last few years, I’m absolutely amazed at what these machines can produce.

I got into 3d printing exactly a year ago now. Initially I was interested in it as a way to learn 3d modeling and eventually transition into CNC milling, which has always been something I’ve been interested in. That’s still in the plans. But I became absolutely fascinated that you could design a 3d model on your computer, and in a few short hours, sometimes less, be holding the physical product in your hands. What a world we live in.

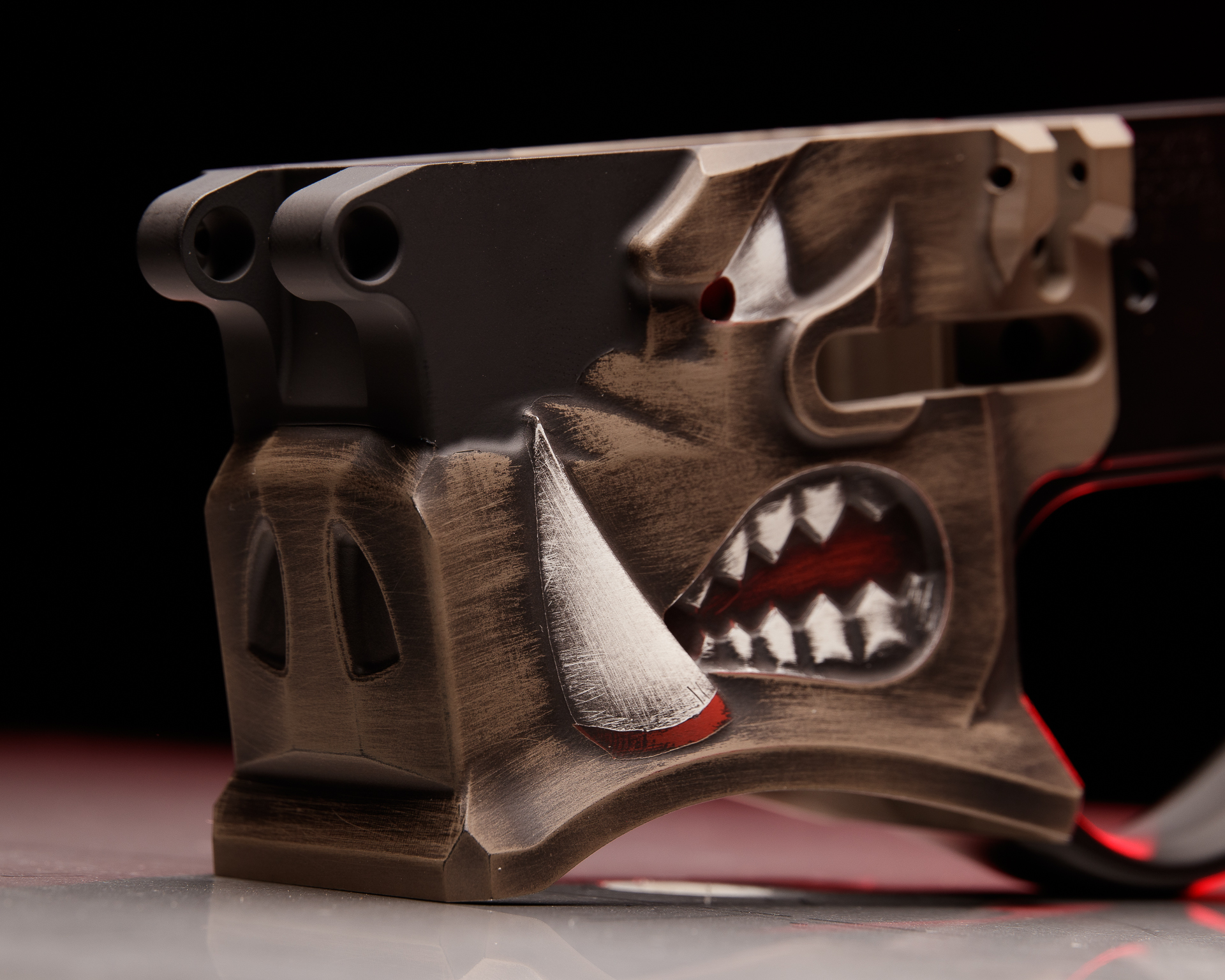

I started with the usual entry level 3d printer, a Creality Ender 3v2. They can be had for a few hundred bucks, but I will say that I was blown away at the quality this thing could produce. I even printed a few pistol frames that I’m still using to this day. Yes, you can print gun parts on them, and yes, they are absolutely functional. (Joe Biden be damned.)

The more I learned and the more I printed, the more impressed with the technology I became. And the more I wanted to somehow incorporate 3d design and printing into Schiwerks. My printer is by far and away my favorite piece of equipment in the shop. And that’s saying something, as I have some awesome equipment. Freakin’ lasers man. But that’s a post for another time.

I’ve made jigs that save me a ton of time and effort. Specialty tools for specific projects. An entire attachment system for tools that goes above our workbench. So it just seemed right to make something in house that our customers would enjoy as well.

We invested in a new printer a few months back: a Bambu Labs X1 Carbon. I’ve been absolutely blown away by this thing. It prints 4-5 times faster than our other printer, with some features that make it an absolute dream to run.

This is where all those mag holders will be brought to life. My plan is to expand our offerings to include holders for other magazines (pistol, AR10, etc) and eventually even mounts to mount rifles and pistols on your walls.

It’s not that I’m just looking for stuff to sell. It’s the fact that I absolutely love designing something from scratch and seeing it come to life. And these are things that I personally use and love. So it only makes sense for me to bring these products to Schiwerks.

Wrapping this rather long post up, I would like to encourage you to check out 3d printing. Dip your toes it. It’s a bit overwhelming at first, but it’s an awesome hobby that can transition into so much more. Feel free to reach out to me with any questions you may have. And until then, happy printing!

~Sam